In the sun-scorched, mineral-rich waters of the Dead Sea, where life seems an impossibility, thrives a remarkable class of biological catalysts known as halophilic enzymes. For decades, the extreme conditions of hypersaline environments were viewed primarily through the lens of ecological curiosity. Today, however, the scientific and industrial communities are awakening to the immense potential locked within these resilient proteins. The study and application of extremophilic enzymes from the Dead Sea are spearheading a quiet revolution in organic synthesis, challenging conventional methodologies and opening doors to more sustainable, efficient, and previously unfeasible chemical processes.

The Dead Sea, a hypersaline lake bordering Jordan and Israel, presents one of the most challenging environments on Earth. With salinity levels nearing ten times that of ordinary seawater, intense ultraviolet radiation, and often extreme temperatures, it has long been considered a place where little can survive. Yet, this very hostility has been the crucible for the evolution of uniquely adapted microorganisms—the halophiles, or salt-lovers. These organisms produce enzymes, the workhorses of biochemical reactions, that are not merely tolerant to high salt concentrations but are functionally dependent on them. This intrinsic stability is the key to their revolutionary application.

Traditional enzymes used in industrial biocatalysis often share a critical vulnerability: they are fragile. They denature, or unravel, when exposed to the high temperatures, extreme pH levels, and organic solvents commonplace in industrial chemical synthesis. This fragility necessitates carefully controlled, often mild, reaction conditions, limiting their scope and economic viability. The search for more robust biocatalysts led researchers to the world's extremes—volcanic vents, polar ice, and saline lakes. Among these, the halophilic enzymes from the Dead Sea have emerged as particularly promising candidates due to their polyextremophilic nature, being adapted to salt, heat, and sometimes even alkaline conditions simultaneously.

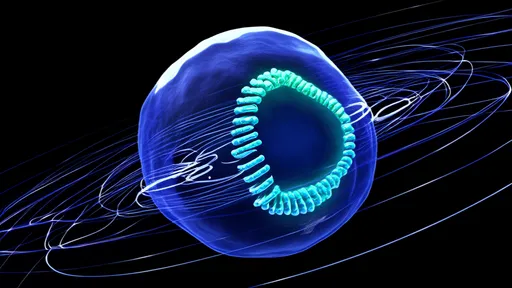

The molecular architecture of these halophilic enzymes is what grants them their superhero-like durability. Unlike their conventional counterparts, their surfaces are adorned with a high proportion of acidic amino acids, such as aspartate and glutamate. This creates a strongly negative surface charge. In a high-salt environment like the Dead Sea, this negative charge attracts a stable hydration shell of water molecules and a cloud of cations (positively charged ions like sodium and potassium). This bound water and ion layer is essential for maintaining the enzyme's three-dimensional structure and, consequently, its function. When placed in the low-water, organic solvent environments typical of many synthesis reactions, this structural integrity persists. The enzyme simply retains its crucial hydration shell, refusing to denature where others would fail.

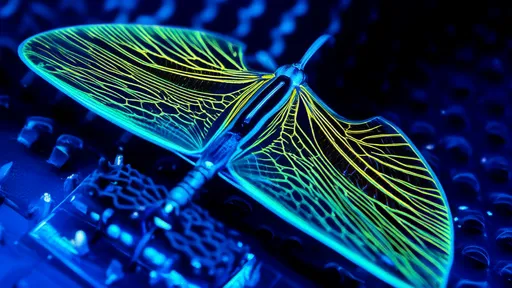

This inherent robustness translates directly into transformative advantages for organic synthesis. One of the most significant is the ability to perform biocatalytic reactions in non-aqueous media. Organic chemists have long dreamed of using enzymes in organic solvents to synthesize compounds that are insoluble in water or to drive equilibrium-controlled reactions in a favorable direction. Dead Sea halophilic enzymes make this a practical reality. They can catalyze reactions like esterifications, transesterifications, and amidations directly in solvents like toluene, hexane, or pyridine, often with high enantioselectivity. This eliminates complex multi-step processes, reduces waste, and provides a direct, green route to chiral intermediates vital for pharmaceuticals, agrochemicals, and flavors.

Furthermore, their stability at elevated temperatures enhances reaction kinetics, leading to faster processes and higher yields. This thermostability also simplifies downstream processing. Unlike reactions using mesophilic enzymes that must be kept cool, processes powered by halophilic enzymes can often be stopped simply by heating the mixture to a temperature that would deactivate contaminants, leaving the target enzyme ready for recovery and reuse. This reusability is a cornerstone of economic and sustainable manufacturing. Early industrial trials report these enzymes being reused for dozens of cycles without a significant loss of activity, dramatically reducing the cost per kilogram of product.

The pharmaceutical industry, with its insatiable demand for enantiomerically pure compounds, stands as a primary beneficiary. The synthesis of single-enantiomer drugs is notoriously challenging and wasteful using traditional chemical catalysis. Halophilic enzymes, such as halophilic lipases and proteases, exhibit exceptional stereoselectivity in organic solvents, enabling the precise synthesis of complex chiral molecules. This not only improves the efficiency of drug manufacturing but also aligns with the principles of green chemistry by minimizing solvent use and hazardous byproducts.

Beyond pharmaceuticals, the applications are vast. In the fine chemicals industry, these enzymes are being explored for the production of novel bio-based polymers, surfactants, and cosmetic ingredients. The food industry utilizes them for the synthesis of specific flavor esters and the modification of fats and oils under conditions that prevent microbial contamination. Even the field of biofuels is investigating their potential in catalyzing transesterification reactions for biodiesel production in the presence of crude, water-containing feedstocks that would incapacitate standard enzymes.

Of course, the path from the Dead Sea to the manufacturing plant is not without its hurdles. The primary challenge lies in production. Culturing the native extremophilic microorganisms is often slow and yields are low. The future lies in advanced biotechnological solutions. Genetic engineers are successfully cloning the genes responsible for these exceptional enzymes into robust, fast-growing host organisms like E. coli or yeast. This allows for large-scale, cost-effective fermentation production. Furthermore, protein engineering techniques like directed evolution are being employed to fine-tune these enzymes for specific industrial processes, enhancing their activity, selectivity, or stability even beyond their natural capabilities.

The exploration of the Dead Sea enzyme library is more than a niche scientific pursuit; it is a paradigm shift in our approach to chemical manufacturing. It represents a move away from harsh, energy-intensive processes towards precise, efficient, and sustainable biocatalytic solutions. By looking to the extremes of nature, scientists are finding the tools to build a greener and more efficient chemical industry. The silent, salty depths of the Dead Sea, once a symbol of barrenness, are now revealed as a treasure trove of biological innovation, proving that sometimes, the most powerful solutions are found in the most unexpected places.

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025