The journey of probiotics from the manufacturing facility to the human gut is a perilous one, fraught with biological obstacles that threaten their viability and, consequently, their promised health benefits. The most formidable of these barriers is the highly acidic environment of the human stomach, a natural defense mechanism designed to break down ingested matter and neutralize pathogens. For live probiotic bacteria, this gastric passage is a gausting gauntlet where survival rates can plummet, rendering many products ineffective before they even reach their intended site of action in the intestines. This fundamental challenge has spurred a significant and sophisticated field of research dedicated to one critical objective: protecting these delicate microorganisms to ensure they arrive alive, active, and in sufficient numbers to confer a therapeutic effect.

The human stomach presents a hostile landscape for any foreign microbe. Gastric acid, primarily composed of hydrochloric acid, can drive the pH down to levels as low as 1.5 during fasting states. This intensely acidic environment is specifically engineered to denature proteins and destroy the cellular structures of ingested bacteria. For unprotected probiotic strains, exposure to this pH for even a short duration—often 60 to 90 minutes—can result in a catastrophic loss of viability, with mortality rates sometimes exceeding 90%. This harsh reality means that a consumer might be ingesting billions of colony-forming units (CFUs) on paper, but only a tiny fraction of those ever complete the journey to the lower gastrointestinal tract where they can colonize and exert their influence on the gut microbiota.

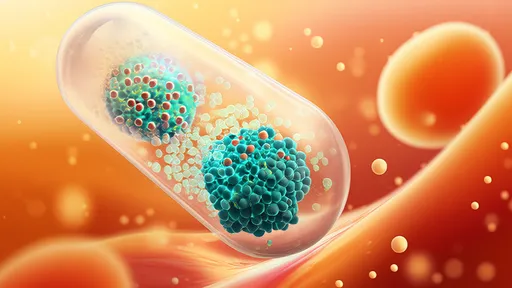

Recognizing this bioavailability crisis, scientists and food technologists have turned to advanced microencapsulation techniques as a potential solution. At its core, microencapsulation is a process of enveloping microscopic particles—in this case, live probiotic cells—within a protective coating or matrix. This technology, often borrowed from the pharmaceutical industry, aims to create a physical barrier between the sensitive bacterial cell and the aggressive external gastric environment. The concept is not merely to create a shell but to engineer a smart, responsive shield that can withstand stomach acid yet disintegrate or become permeable upon reaching the more neutral pH of the small intestine, thereby releasing its payload precisely where it is needed.

A variety of materials are employed to construct these microscopic fortresses, each with distinct properties and advantages. Biopolymer-based systems are among the most prevalent and are favored for their biocompatibility and generally recognized as safe (GRAS) status. Alginate, a natural polysaccharide derived from brown seaweed, is a classic example. It can form a stable gel matrix, known as a bead, through ionic cross-linking with calcium ions. This gel creates a dense network that hinders the diffusion of hydrogen ions from the stomach acid, offering a buffer for the entrapped bacteria. However, pure alginate beads have limitations, including porosity that can allow acid penetration and instability in the presence of certain salts found in the gut. To overcome this, researchers often combine alginate with other polymers like chitosan, starch, or gums to create coacervates or complex coatings that are far more resilient.

Another prominent category of encapsulation materials includes proteins, such as whey protein, gelatin, and casein. These can form protective gels or coatings through processes like thermal denaturation or enzymatic cross-linking. Lipid-based encapsulation is another strategy, where probiotics are dispersed in a fat matrix or coated with layers of waxes or emulsified fats. Lipids are inherently resistant to acid and can provide excellent protection during gastric transit. More recently, advanced techniques like spray drying and freeze drying have been adapted for encapsulation. In these processes, probiotics are suspended in a protective solution (e.g., sugars like trehalose or gums) and then rapidly dried, leaving the cells embedded within a solid, protective matrix of the carrier material. This matrix acts as a physical barrier during storage and gastric passage.

The choice of encapsulation material is only one part of the equation; the method of application is equally critical. Extrusion is a simple and common technique where a probiotic-polymer mixture is dripped into a hardening solution, forming gel beads. While cost-effective, it can produce beads with a larger size distribution. Emulsion techniques allow for the creation of much smaller, more uniform capsules by forming a water-in-oil emulsion before hardening the internal aqueous droplets containing the bacteria. For industrial-scale production, spray coating is often employed, where probiotic cells are fluidized in a chamber and sprayed with a coating solution, building up a protective layer particle by particle. Electrospraying and electrospinning are emerging technologies that use electrical forces to create ultra-fine fibers or particles with a high surface-area-to-volume ratio, offering potentially superior protection and controlled release profiles.

The ultimate test of any encapsulation technology is its performance in simulated human digestion models. These in vitro tests meticulously replicate the conditions of the stomach (low pH, presence of pepsin enzyme, specific residence time) and the small intestine (higher pH, presence of bile salts and pancreatin). Researchers use these models to quantify the survival rate of encapsulated probiotics compared to unprotected (free) cells. The results consistently demonstrate the profound efficacy of a well-designed encapsulation system. Where free cells may see a 4-5 log reduction in viable count (a 99.99% die-off), encapsulated cells can often achieve survival rates exceeding 80% or even 90%, preserving a therapeutically relevant dose of live bacteria. This data is the primary evidence that drives the adoption of these technologies in product development.

The successful implementation of probiotic encapsulation has far-reaching implications that extend beyond the laboratory and into the global market. For consumers, it translates to tangible efficacy. They can trust that the product they are purchasing will deliver on its promise of supporting digestive health, enhancing immune function, or whatever its intended benefit may be. This trust is the cornerstone of brand loyalty in the highly competitive functional food and dietary supplement industries. For manufacturers, overcoming the survival challenge through encapsulation is a key product differentiator and a powerful marketing tool, allowing them to make validated claims about "stomach-acid resistance" or "targeted delivery." This technological edge can define a product's success in a crowded marketplace.

Despite the significant progress, the field of probiotic encapsulation is not without its ongoing challenges and areas for future innovation. A primary concern is scaling up laboratory techniques to cost-effective, high-volume industrial manufacturing without compromising the protective quality or viability of the probiotics. There is also a continuous search for novel, even more effective coating materials, particularly from sustainable and natural sources to meet clean-label consumer demands. Furthermore, research is delving into next-generation "smart" encapsulation systems that could respond to specific triggers in the intestine, such as enzymes from specific gut bacteria, allowing for even more precise and timed release. The exploration of synbiotics—combining probiotics with their preferred prebiotic nutrients within the same capsule—is another exciting frontier, as the prebiotic can not only act as a protective matrix but also provide immediate nourishment for the probiotic upon release, boosting its activity.

In conclusion, the challenge of ensuring probiotic survival through the gastric system is a complex puzzle that sits at the intersection of microbiology, material science, and food engineering. The development and refinement of microencapsulation technologies represent a monumental leap forward in solving this puzzle. These ingenious protective strategies are fundamentally transforming the probiotic industry, shifting it from a market of uncertain promises to one built on proven efficacy and reliable delivery. As research continues to push the boundaries of what is possible, the future promises even more sophisticated and effective methods to safeguard these beneficial microbes, ensuring that they can successfully complete their critical mission to promote human health and well-being.

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025